Automation in the chemical industry

Automation in the chemical sector is still often viewed as a luxury or a future goal. But let’s get straight to the point: in an industry where safety, precision, and scalability are critical, automation is no longer a nice-to-have, it’s a must-have.

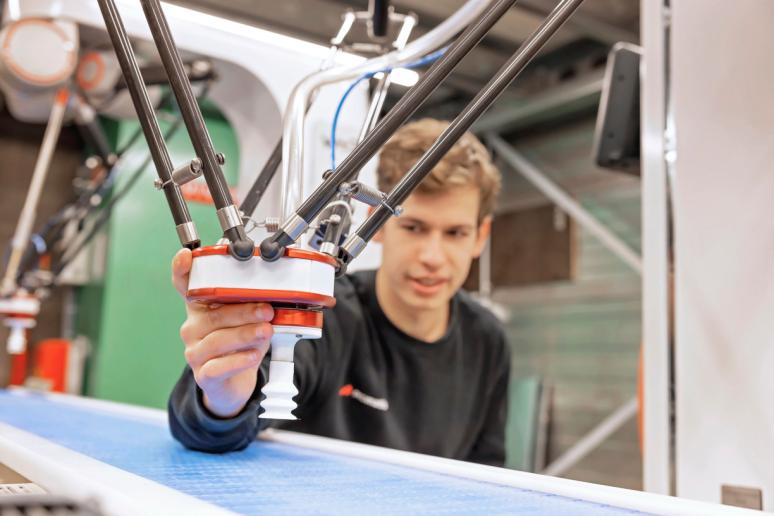

At Promation, we witness daily how robots, cameras, and smart systems don’t just improve production safety and efficiency, they open new doors for innovation, traceability, and sustainability. It’s not about replacing people, but about smart integration that monitors, controls, analyzes, and adapts.

It’s time to let go of the old idea that “robots take our jobs.”

Why automation in chemistry is different from other sectors

The chemical industry is unique. It deals with hazardous substances, strict regulations, high temperatures, and zero tolerance for error. That’s what makes automation not only valuable, but essential.

Unlike other sectors, it’s not just about speed or cost-saving. Here, it’s about process control, safety, and quality. Automation must handle this complexity and anticipate it.

Real example: At a detergent manufacturer, we integrated an inspection camera that detects minor color changes in real time during batch mixing. The result? Greater consistency and early detection of anomalies before thousands of liters are lost.

Automation solutions in the chemical sector

At Promation, we build tailored systems. But some applications come up over and over again:

1. Robotic arms for filling and packaging

For liquids or powders being filled into drums, bottles, or IBCs, robotic arms ensure precise, safe, and consistent filling, no exposure for operators, no spills.

2. Vision systems for quality control

Cameras, like the Cognex, that check caps, verify labels, read batch codes or even detect micro-contamination. They do this 24/7, without getting tired and with a consistency a human cannot match.

3. Automated sample collection

In-line sample collection is essential for quality control. Automation makes it safer, more consistent, and more reliable.

4. Automated traceability through data logging

Every temperature, batch, adjustment, and intervention can be automatically recorded, ready for audits and compliance.

5. Smart recipe execution and dosing

Automated loading of recipes and dosing parameters minimizes human error and ensures consistent output, every batch.

Automation increases safety, not risk

There is still often a perception that automation is associated with new dangers: colliding robots, error messages, technical complexity. But the reality is the opposite.

By deploying automated systems, paired with customization, you just take people away from high-risk areas. Consider:

- Vapors

- Toxic substances

- Hot processes

Moreover, our robots are equipped with sensors, light curtains and other safety techniques. They stop at the slightest error or deviation. And the best part? They not only make work safer, but also lighter and more consistent. Less manual handling = less risk of errors and injuries.

How to get started with automation?

Many chemical companies are unsure where to begin with automation. Our advice? Start small, for example, by automating sample collection or digitising recipe management. This allows you to take a smart first step without major changes.

At Promation, we offer a free analysis to identify automation opportunities in your production process. With our ROI configurator, you can instantly calculate which solution fits your business and how quickly your investment will pay off.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Automation in chemistry is a strategic decision

Investing in automation today means investing in efficiency, compliance, safety, and long-term sustainability. The chemical industry has high standards, rightfully so. But with the right partner and the right technology, automation becomes a strategic lever.